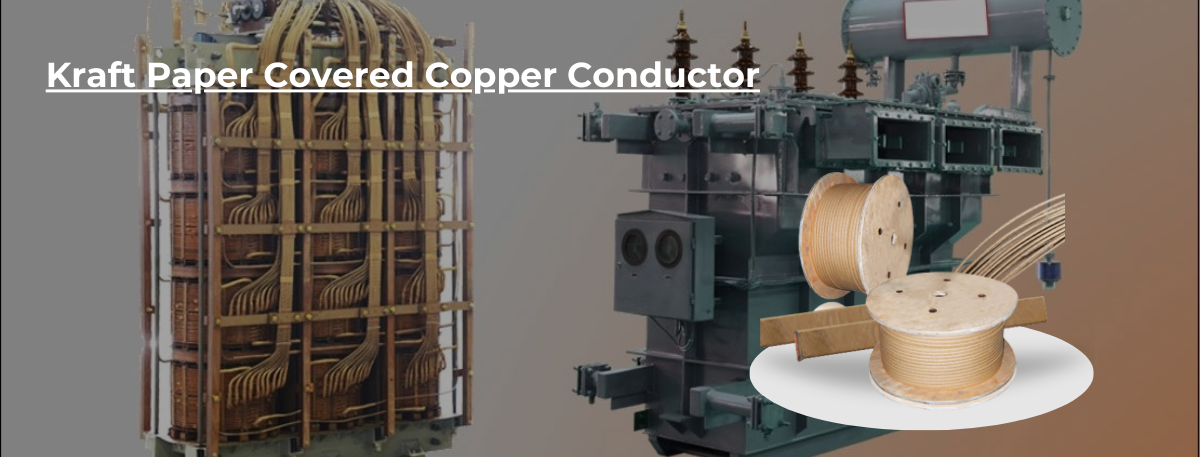

Kraft/Crepe Paper Covered Copper Conductor

Product Description

Kraft paper insulation is most commonly used in oil filled transformers. The plain kraft papers are wrapped in number of layers on conductors, to acquire the needed insulation strength. However, plain kraft paper has limitations of the flexibility and leads to breakage of insulation in tight shaping of the coils. For this purpose, kraft papers are fabricated or creped.

The folds made in creping process, increases the elasticity and flexibility during shaping of coils. It also enlarges the surface area of insulation and absorbs insulating oils resulting in better insulation and heat dissipation during operation.

Application

Crepe Kraft Paper Insulated Copper Cables are mainly used as an insulation in oil cooled transformers, current transformers of type IMB, CT, CVT as leads and shields. Crepe paper has 300% more strength in machine and cross machine direction and hence is more resistant to breakage. It can also take various shapes of the surface being insulated. The cable is wound on FRP Rings, 3 to 12 turns as per transformer application. This is also most suitable as lead wire and terminal wires of PT windings.

| Specification | Size Range | |

|---|---|---|

| Kraft/Crepe Paper covered | IS - 8130 | 2.5 sq.mm to 200 sq.mm |

| copper conductor | IS - 8572 |